Woodgate Primary Academy, Pease Pottage

Windhive Performance Case Study

Credit: Andy Marshall

“Based on our experience at Pease Pottage Primary School, I would have no hesitation in recommending Ventive”

Introduction

Ventive was approached by Paine Manwaring to provide a ventilation solution for a new primary school being built to support a large housing development in Sussex. Paine Manwaring were contracted by the Thakeham Group.

The state-of-the-art facility included five modern classrooms, a main hall, library, multi-functional space, and a dedicated special educational needs room. Designed to serve 210 pupils, the school now offers a vibrant, future-focused learning environment for students from the local community.

In addition to meeting Indoor Air Quality (IAQ) standards, the school’s aim was to use a passive ventilation system without the heat loss of other Natural Ventilation systems, in order to reduce energy consumption, Carbon emissions and operational costs.

Ventive Windhive® was proposed as the preferred choice due to its proven performance and low energy consumption.

This report presents performance data for the units, showing the key parameters of CO₂ concentration, indoor air temperature, and outdoor air temperature. The study also details the installation process, data collection methods, and compliance with regulations regarding IAQ and overheating mitigation – two critical parameters for indoor air quality in schools.

“Woodgate Primary Academy exemplifies our commitment to placemaking at Woodgate. We funded and delivered the school at an early stage of the development because we knew it would play a crucial role in the creation of a thriving new community. We are grateful to everyone who played their part in helping us design a school to make West Sussex proud.”

Rob Boughton, CEO of Thakeham Group

Executive Summary

A single Windhive® unit and purge louvre were installed in each of the classrooms (maximum occupancy 33 people) and the library. In the Hall, external wall louvres and roof windows combine to create a simple yet effective natural ventilation system. The Ventive Hub monitors indoor air quality in all the spaces and allows each unit to respond to the requirements in that room.

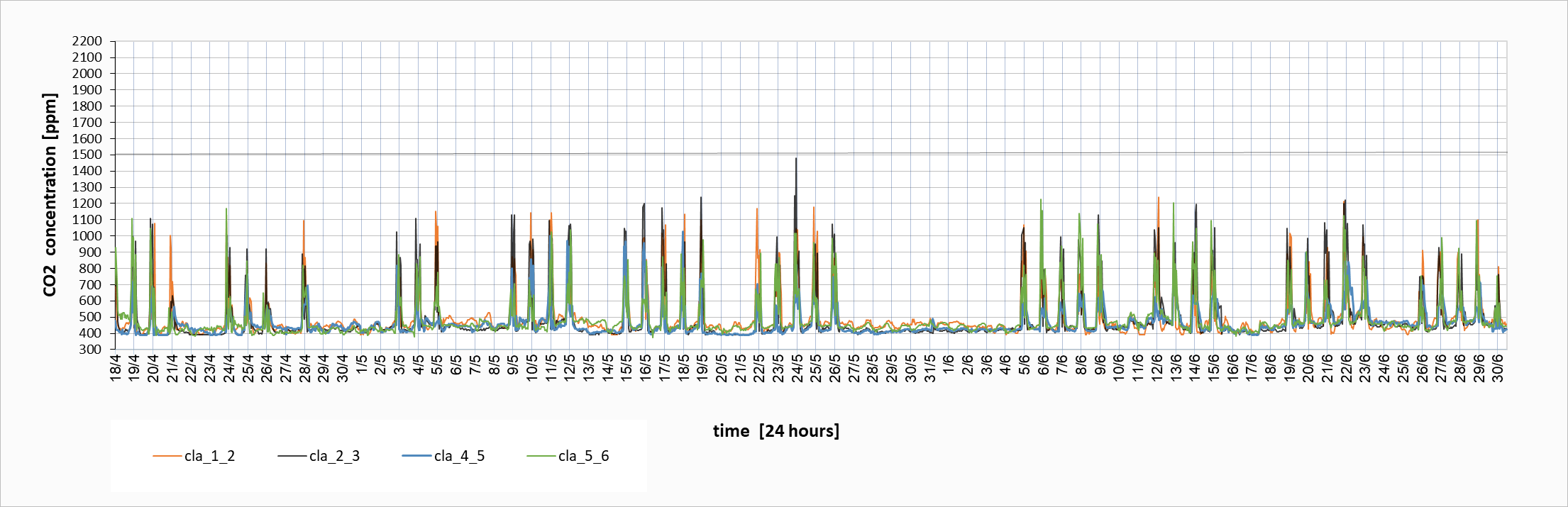

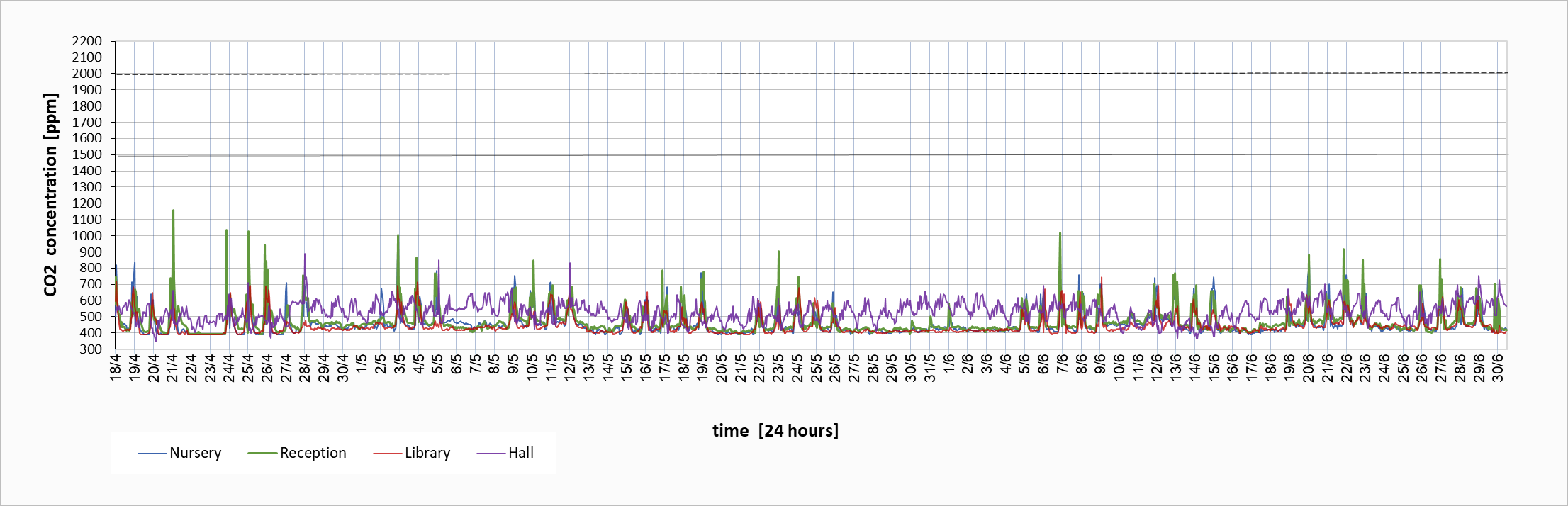

The results show that CO₂ levels were consistently well-controlled, only occasionally exceeding 1,500 ppm. Average daily CO₂ concentrations during occupancy remained well below 1,000 ppm, significantly surpassing regulatory recommendations.

Indoor temperatures generally remained within comfortable limits indicating that Heat Recovery, Cross-Flow Ventilation and Night Cooling play an important role in reducing heating need in Winter while reducing the risks of overheating in the Summer.

This empirical data shows compliance with BB101, TM-52 and the new Construction Framework output specification (CF25) issued by the Department for Education.

Design

Windhive® is a market-leading passive ventilation with heat recovery (PVHR) system, designed to harness the natural forces of air buoyancy and wind speed. The system supplies pre-warmed fresh air, maintaining low CO₂ levels and reducing pollutants in a cost-effective manner. The Ventive Hub senses the classroom environment and enables the systems to respond to the needs of the occupants, reacting to CO₂ levels (proxy indicator of occupancy) and temperature – both inside and outside of the building.

One system was specified per classroom with a ceiling-mounted diffuser to regulate the exhaust, supply and by-pass. Façade louvres were specified to allow secure night-time purge and cross-flow ventilation when required.

Installation

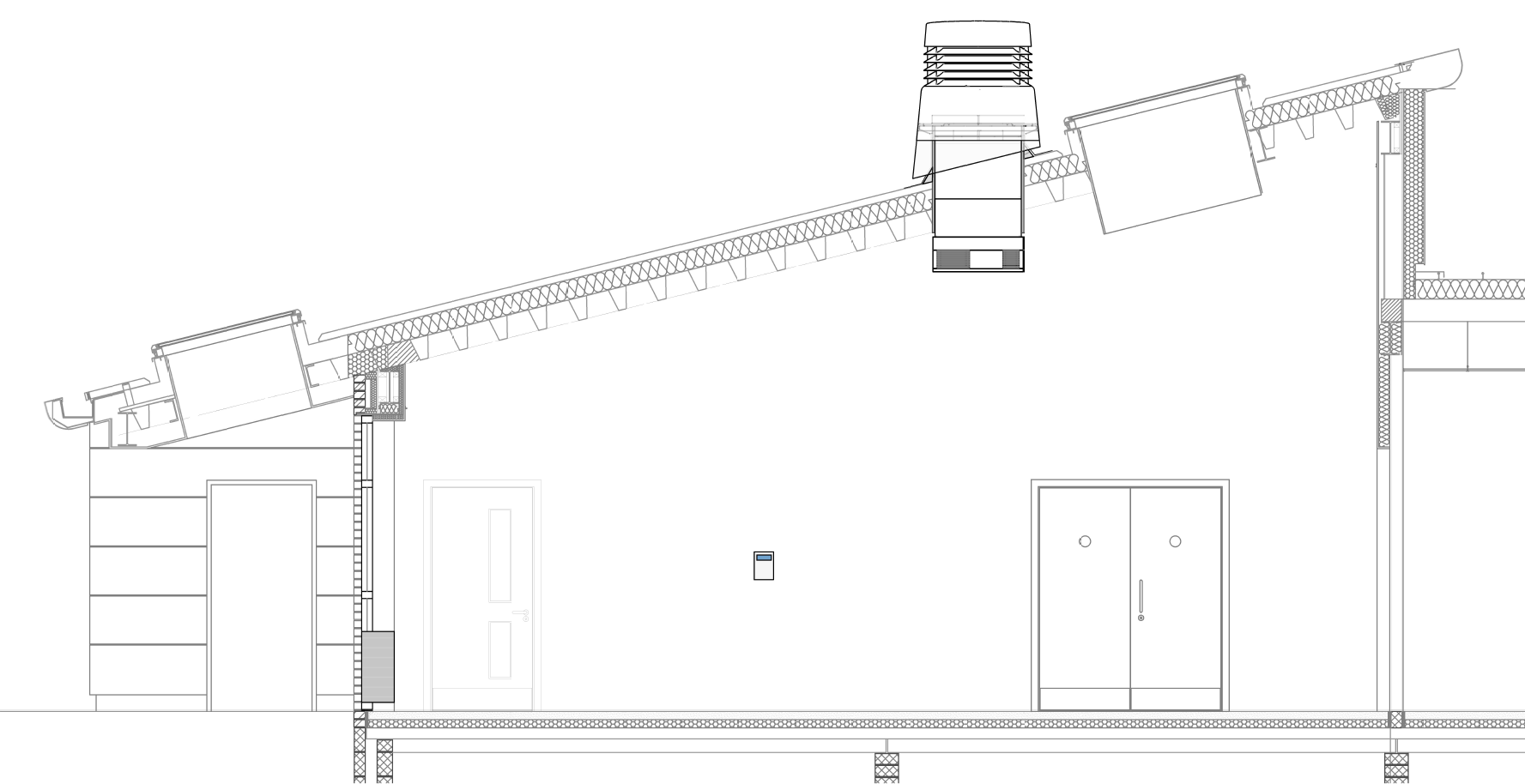

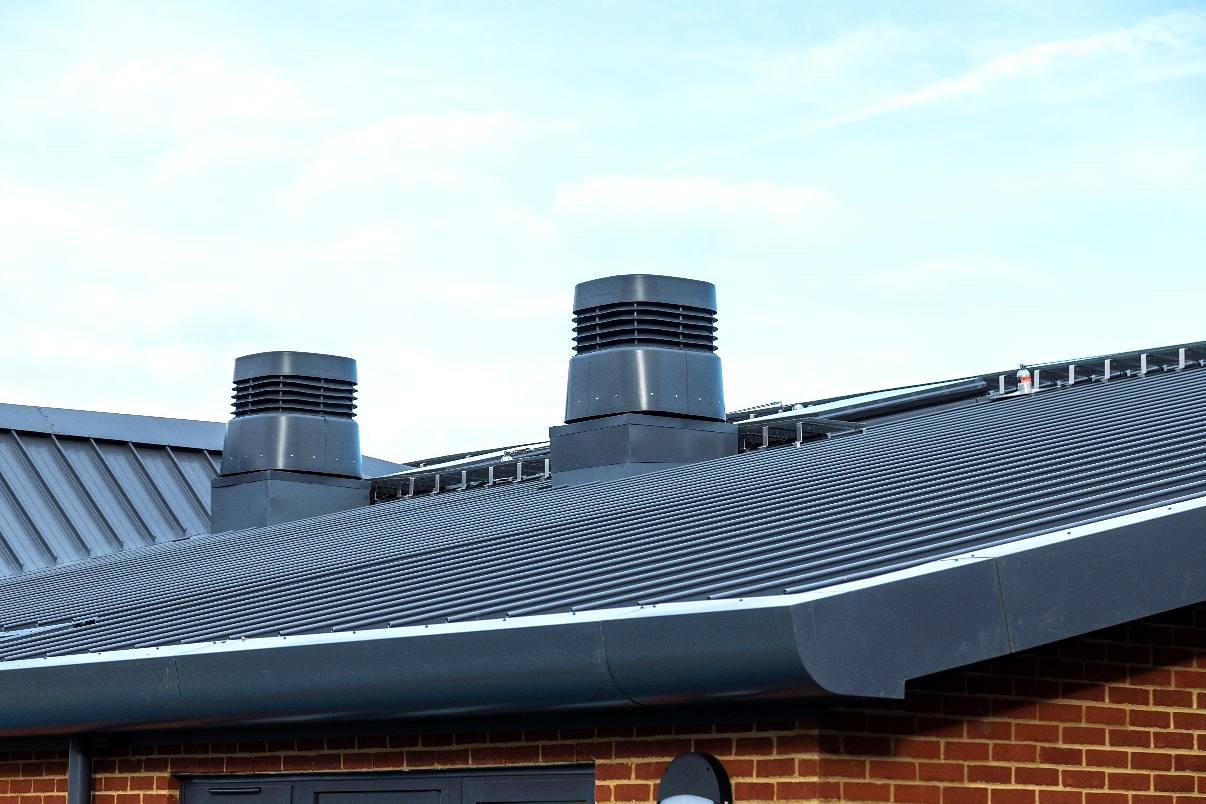

Each Ventive Windhive unit consists of a cowl, heat exchanger and diffuser. The modules are fixed into and onto a purpose-built upstand, allowing for flashing into the roof detail. This installation method reduces time spent on site, reduces risk, and enables efficient commissioning.

The entire system is lowered into position through the upstand opening. The internal diffuser is fixed to the heat exchange module and wired in.

Once checked for operation, the external diffuser housing can be fitted.

Above the roof, the cowl allows fresh air to flow into the classroom, recovering energy as it does, while maintaining separate pathways to ensure no mixing or recirculation of stale/contaminated air occurs.

Louvres installed beneath the windows and integrated into the glazing detail allow for purge and cross-flow ventilation if required.

Data Collection and Analysis

The Hub constantly collects environmental and performance data, which is visible to Ventive in real time, logged remotely, and analysed to fine-tune the systems. This allows for early detection of issues and optimisation of efficiency.

Carbon Dioxide

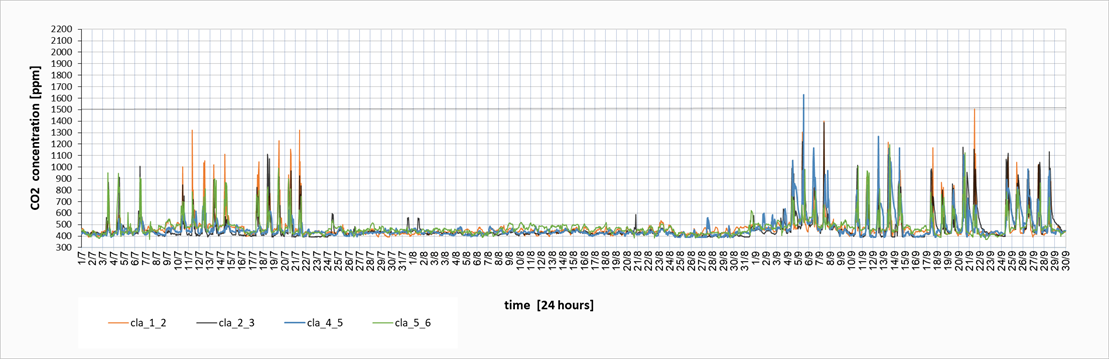

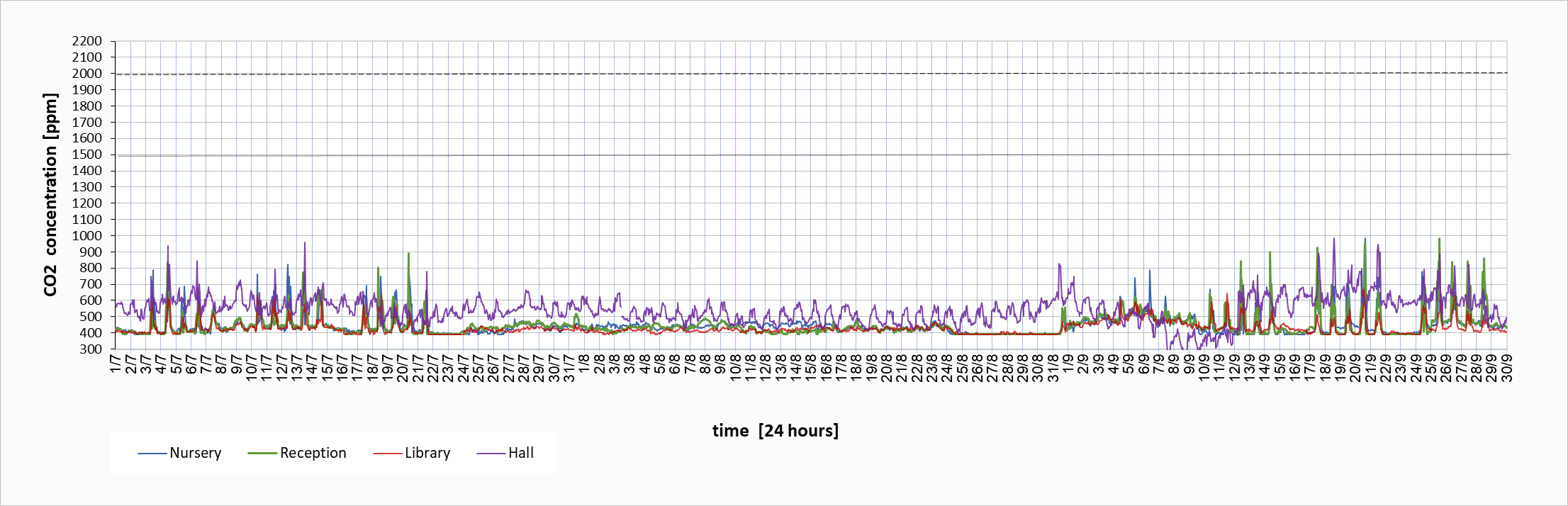

The graphs below show CO₂ levels in each classroom, the library, and the Hall from April to September:

Temperature

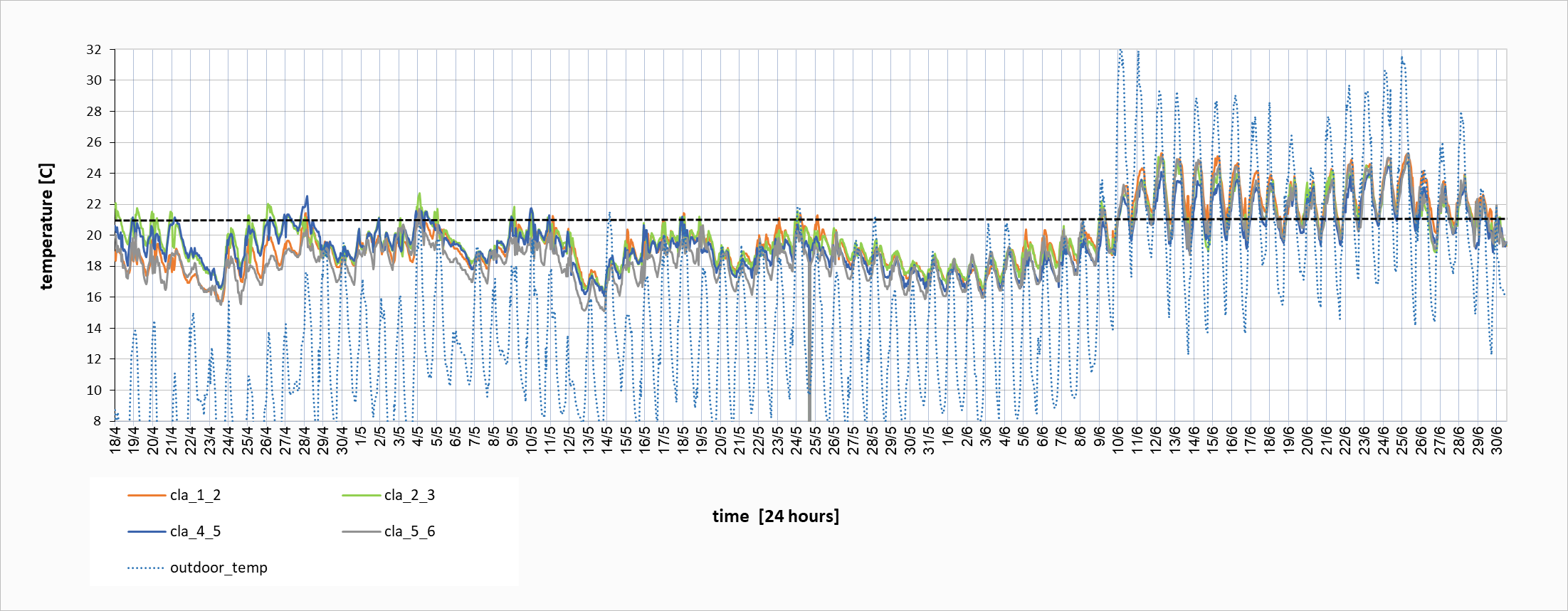

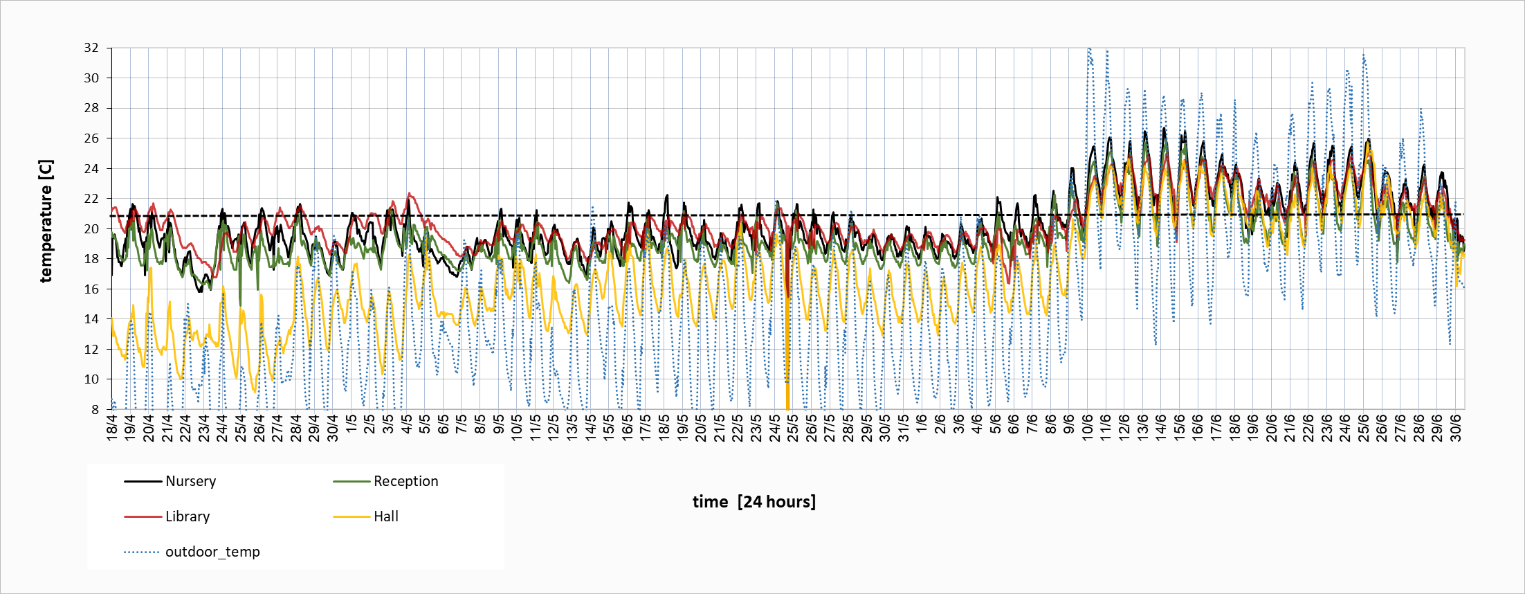

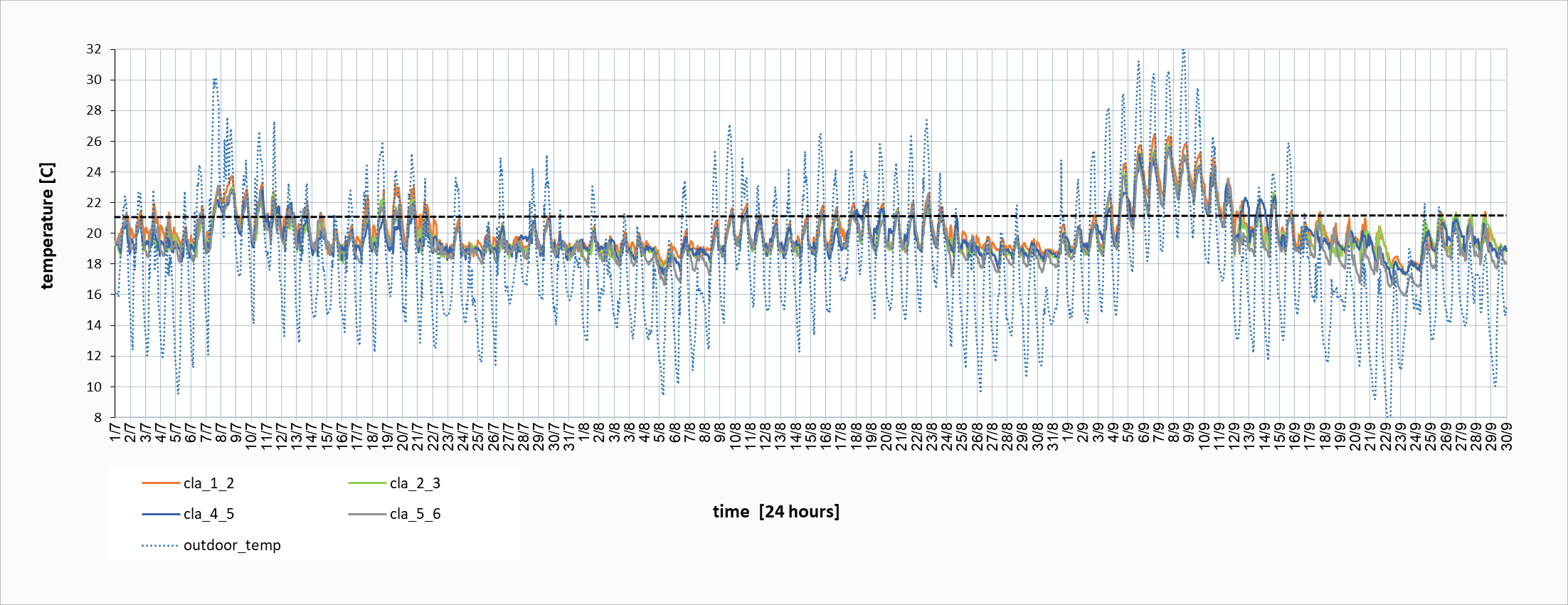

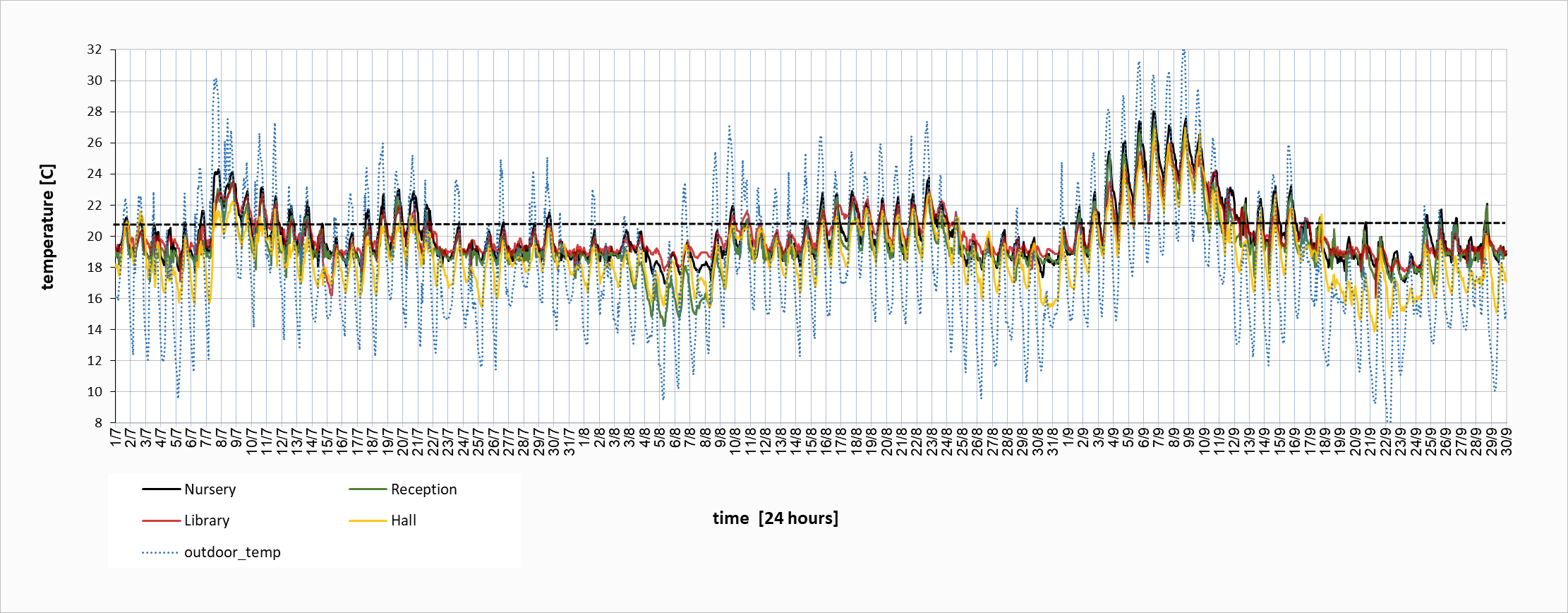

The graphs below present indoor and outdoor temperatures for the same period:

Summary

The Windhive systems have consistently delivered effective ventilation at a lower cost than standard alternatives. They maintain stable, comfortable indoor air quality while recovering excess heat from stale air. Continuous monitoring ensures ongoing optimisation, with system refinements supporting both performance improvements and product development.

10/10 Positive Experience Working with Ventive

“Working with Ventive has been a genuine pleasure. The team provided clear and detailed explanations throughout the process, ensuring full transparency and understanding of the system. All plant and equipment were delivered on schedule, and the system was commissioned without issue. Since completion—several years ago—we have not experienced any call-backs, which is a testament to the quality and reliability of both the installation and the support provided. Based on our experience at Pease Pottage Primary School, I would have no hesitation in recommending Ventive for the design and installation of natural ventilation systems. Their team demonstrated professionalism and technical expertise throughout the project, and the system has continued to perform reliably since its completion.”

Tony Farhall

Project Manager