Holbrook Primary School

Windhive Performance Case Study

Introduction

Ventive was approached by Rigg Construction to provide a suitable Passive Ventilation solution for a new classroom block at a primary school in Trowbridge, that was aiming to be Net Zero Carbon.

Project Team

- Principal Contractor: Rigg Construction (Southern) Ltd

- Architects: Footprint Architects

- Project Manager: CMS Project Managers & Surveyors Ltd

- Structural & Civil Engineers: Pope Consulting

- M&E Engineers: Pro-Air

Designed to be Net Zero Carbon in Operation, Holbrook Primary School is a purpose built KS2 school building focused on healthy learning environments. The new school building has successfully provided an uplifting learning environment, that effectively supports educational activities, school behaviour and wellbeing.

Built using a traditional form of construction, the project achieved net zero Carbon in use through innovative design methods, installation of solar PV, insulation, and Windhive PVHR (Passive Ventilation with Heat Recovery) – reducing convective heat loss, energy consumption, Carbon emissions and operational costs.

This report presents performance data for the units, showing the key parameters of CO₂ concentration, indoor air temperature, and outdoor air temperature. The study also details the installation process, data collection methods, and compliance with regulations regarding IAQ and overheating mitigation – two critical parameters for indoor air quality in schools.

On Net Zero Carbon Schools, the award winning Footprint Architects state they “are committed to developing schools and colleges that are environmentally conscious and respond positively to the climate emergency. We believe that all schools should be low energy, zero carbon, cheap to run and easy to maintain. Sustainable school building design is good for both the planet and the future of our young people.”

Executive Summary

A single Windhive® unit and purge louvre were installed in each of the classrooms (maximum occupancy 33 people). The Ventive Hub monitors indoor air quality in all the spaces and allows each unit to respond to the requirements in that room.

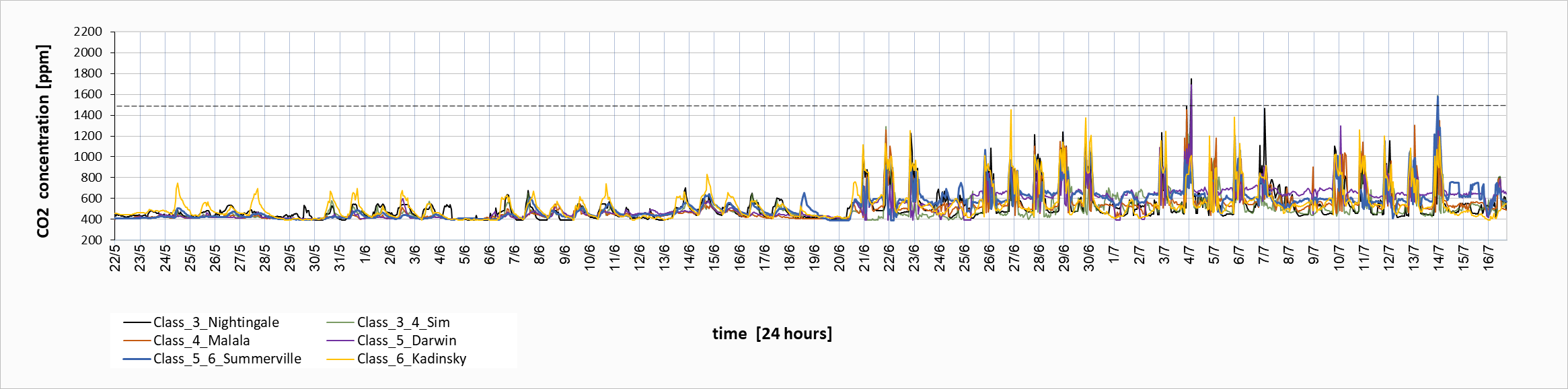

The results show that CO₂ levels were consistently well-controlled, with the average daily concentration during occupancy remaining well below 1,000 ppm – significantly surpassing regulatory recommendations.

Indoor temperatures generally remained within comfortable limits indicating that Heat Recovery, Cross-Flow Ventilation and Night Cooling play an important role in reducing heating need in Winter while reducing the risks of overheating in the Summer.

This empirical data shows compliance with BB101, TM-52 and the new Construction Framework output specification (CF25) issued by the Department for Education.

Design

Windhive® is a market-leading passive ventilation with heat recovery (PVHR) system, designed to harness the natural forces of air buoyancy and wind speed. The system supplies pre-warmed fresh air, maintaining low CO₂ levels and reducing pollutants in a cost-effective manner. The Ventive Hub senses the classroom environment and enables the systems to respond to the needs of the occupants, reacting to CO₂ levels (proxy indicator of occupancy) and temperature – both inside and outside of the building.

One system was specified per classroom with a ceiling-mounted diffuser to regulate the exhaust, supply and by-pass. Façade louvres were specified to allow secure night-time purge and cross-flow ventilation when required.

Installation

Each Ventive Windhive unit consists of a cowl, heat exchanger and diffuser. The modules are fixed into and onto a purpose-built upstand, allowing for flashing into the roof detail. This installation method reduces time spent on site, reduces risk, and enables efficient commissioning.

The entire system is lowered into position through the upstand opening. The internal diffuser is fixed to the heat exchange module and wired in.

Once checked for operation, the external diffuser housing is fitted.

Above the roof, the cowl allows fresh air to flow into the classroom, recovering heat as it does, while maintaining separate pathways to ensure no mixing or recirculation of stale/contaminated air occurs. It is optimised to accept air from 360 degrees without moving, due to its patented design, which ensures both top-down displacement and enhanced extract. Finished to match the roof pitch, the cowl is designed to integrate into all types of roof finishing.

Colour-matched Louvres installed beneath the windows and integrated into the glazing detail allow for purge and cross-flow ventilation when required to mitigate overheating.

Data Collection and Analysis

The Hub constantly collects environmental and performance data, which is visible to Ventive in real time, logged remotely, and analysed to fine-tune the systems. This allows for early detection of issues and optimisation of efficiency.

Carbon Dioxide

The graphs below show CO₂ levels in each classroom from May to July 2023, showing pre-completion, handover of the school and then the occupied period starting from 21st June.

Temperature

The graph below shows indoor and outdoor temperatures for the same period and interestingly during an extreme heat wave:

Summary

During a period of extreme weather, the Windhive systems consistently delivered effective ventilation at a lower cost than standard alternatives, maintain stable, comfortable indoor air quality while recovering excess heat (or coolth) from stale air. Continuous monitoring ensures ongoing optimisation, with system refinements supporting both performance improvements and product development.