Testing, testing – the power of research.

There is a lot of hype around Net Zero at the moment – everything seems to save the world if you buy it and many funds are meeting their ESG targets by offsetting rather than deep investment in solutions that can actually achieve the reductions needed.

At Ventive, we believe that to achieve global Carbon emissions reduction by developing sustainable buildings and decarbonising heating, we need innovative solutions that actually deliver. That drives our investment in research – both academic and experimental.

We know that persuading clients to do something ‘different’ can be a challenge, but it is part of our job as pioneers (among many fantastic other innovators) to do so. Having said that, it is critical that when our products are installed, they work as expected and delight our customers.

One recent example is our work with BSRIA and Brunel University on the impact different ventilation strategies have on “viral spread” in an office or school environment. Our study was carried out in a 40m2 office, using droids (complete with perspex “divider” screens and masks) to mimic human occupants. We gave one of the droids Covid-19 – using detectable CO2 gas as a proxy for infected breath – and monitored what happened.

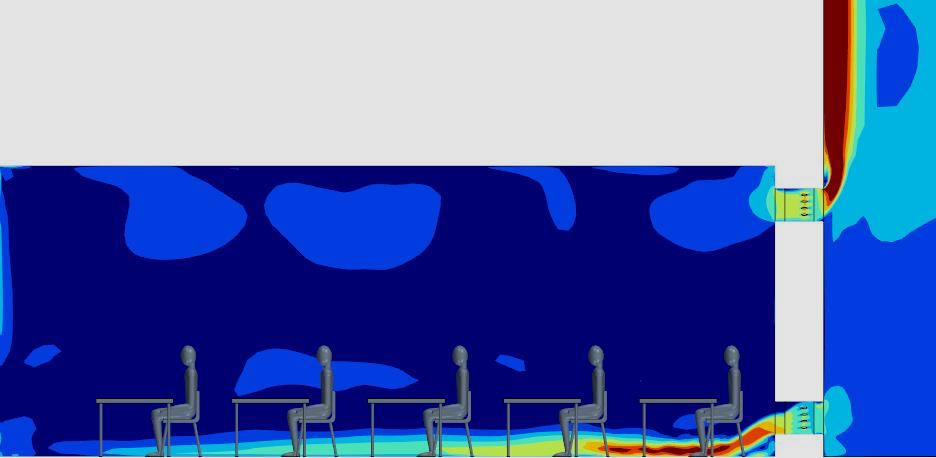

As these different scenarios were being set-up and monitored, we created a digital twin of the room and its “occupants” so that we could correlate the modelling to what was happening in real life. This allowed us to create a reliable digital model to further study the impact of different strategies on the internal environment and how healthy it will likely be.

The results were eye-opening to say the least. You can read the full details of the testing and its results here. But the headline outcome was that some methods of ventilation spread the virus from our sick droid to her plastic colleagues in just 4 minutes. It became apparent that rather than sticking to rigid ventilation rates (eg 15l/s) the biggest impact appears to be HOW that air is distributed into and around the space, with displacement ventilation coming out on top. Also – no mixing. Any recirculation system (dilutive or not) will encourage the spread of any airborne/aerosolised pathogen back into the occupied space and increase the risk of contamination.

This shows the power of research and testing in informing product development, so we can deliver the best possible outcomes for our clients.

Another area that we have been exploring is modern methods of construction (MMC). We think that this approach to offsite construction will help our industry deliver more efficient buildings in a less wasteful way, so ensuring our systems can work in the MMC environment is crucial. We have been working with the Construction Innovation Hub and the Manufacturing Technology Centre to ensure our products are refined and can work at scale in this market.

We have also been fortunate to work with clients who are keen to apply new approaches to help solve significant problems. For example, Nottingham City Council has used Ventive’s Home system (all-in-one heating, hot water, ventilation and energy storage solution) to retrofit its properties in a pilot scheme as it heads towards its net zero targets in 2028. This has allowed us to start monitoring in-situ performance which will both demonstrate efficacy and feed back to product development.

Our aim is to work with these Councils to help identify ways that the UK can not only enhance the energy performance of its older dwellings, but also to make them more comfortable and affordable for occupants.

To some organisations, time and money invested in research may seem like a luxury. But I believe that with the major issues we face, understanding the science and demonstrating outcomes to specifiers are crucial steps. As engineers, we need to understand the consequences of our designs, and it’s only by constant research and testing that we can offer predictable outcomes for building owners and occupants.

Rob Morrison

Managing Director